High Density Thickened Tailings (HDTT) Storage

High Density Thickened Tailings (HDTT) Storage

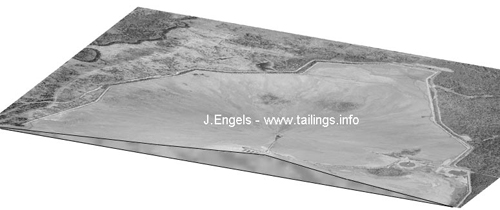

Figure 1: Thickened discharge at Kidd Creek, ON, Canada (left) and at Mt Keith, Western Australia (right) (© Jon Engels)

Introduction

Thickened tailings, as the name suggests, involves the mechanical process of dewatering low solids concentrated slurry (Fourie 2003). This is normally achieved by using compression (or high rate) thickeners or a combination of thickeners and filter presses. High Density Thickened Tailings (HDTT) are defined as tailings that have been significantly dewatered to a point where they will form a homogeneous non-segregated mass when deposited from the end of a pipe (Welch 2003). They are not to be confused with paste tailings which are a higher (and more expensive) degree of thickening to produce very dense slurry that is often pumped to its final storage facility using positive displacement pumps (however, centrifugal pumps can be used to pump paste where the tailings properties are favourable). HDTT is often defined in industry where the tailings have a high yield stress (typically higher than 20 Pa but no higher than 100 Pa), do not require deep cone or paste thickening technology, bleed water upon deposition and can be transported using conventional centrifugal pumping.

The idea of HDTT is to stack the pulp to form a self supporting conical pile thus reducing the height and retention forces of the containing perimeter embankments. Increasing the thickness of the tailings pulp (i.e. increasing the %solid concentration) creates higher beach slopes angles in comparison to tailings discharged with a higher content of water (i.e. lower %solid concentration). The tailings are generally discharged from topographical high points within the tailings storage facility or by riser towers or central ramps (ICOLD and UNEP 2001). Liberated water after deposition and any surface runoff is collected in a pond at the toe of the pile. Typical slope angles of 1 – 3.5 degrees can be achieved to form a self draining easy reclaimable shape (ICOLD and UNEP 2001). Paste tailings disposal often achieve higher beach slope angles compared to HDTT.

History

In 1973 the Falconbridge owned Kidd Creek Metallurgy Plant in the town of Timmins, Ontario, Canada was the first site to utilise surface thickened disposal of tailings (Engels and Dixon-Hardy 2004). The conventional storage facility was converted to HDTT to eliminate further raising of the traditional retaining embankments that were situated on very soft and sensitive clay foundations (ICOLD and UNEP 2001). The tailings are discharged from spigots on a central ramp that is currently 20m high. At the base of this ramp is the 32 m diameter, high compression thickener that produces a slurry density of 60 – 65% solids (Golder 2005).

Figure 2: Cross section of the Kidd Creek CTD facility (© Jon Engels)

Discussion

Operating costs are higher for thickened disposal due to the associated dewatering costs. However, there are significant advantages to thickening tailings. Perhaps the most important is that higher volumes of water can be recovered and the seepage and evaporation losses from the tailings storage facility can therefore be minimised. Sustainable water use in the mining industry is becoming increasingly more important (Welch 2003). The potential for recovering high volumes of water at the plant (by the thickeners) eliminates the losses associated with the transport and storage of water either at the tailings facility or in holding ponds (Fourie 2003). Environmental problems such as seepage, spillage of process water and the potential for water to act as a transporter for tailings flows (e.g. embankment breach) is significantly reduced. Some other main advantages to thickening tailings are:

The final point relating to beach slope is an important design parameter for thickened tailings storage facilities. In conventional tailings deposition the beach slope is very low, often around 1% (less than 1 degree) and facility design can be flexible if there is a slight variation in this parameter. However, for thickened tailings where the variation is often greater with increased beach slopes, this can have a big impact on embankment design heights. An under estimation of the beach slope (flatter beach slope) can result in complications in construction schedules where future embankment construction stages have to be brought forward to prevent loss of freeboard. This can create unexpected operational costs thus advancing programmed OPEX for a mining operation.

Besides the costs associated with thickening the tailings, many mine operators are reluctant to switch from conventional to thickened storage even though wet deposition is more problematic. The argument could also lead to the fact that high density thickened tailings disposal is relatively unproven. However, over recent years there has been acceleration in interest towards HDTT by mine operators. Some of the reasons why are as follows:

In the future, the benefits of high density thickened tailings storage will be more prominent, particularly as environmental regulations tighten and increased pressure is placed on the mining industry to become more sustainable (Welch 2003).