Tailings Storage Guidelines and Standards

Tailings Storage Guidelines and Standards

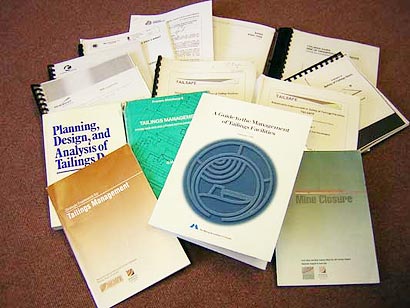

Figure1: Key tailings management documents used in industry

Introduction

There exists a large volume of documentation relating to all aspects of design, construction, operation and closure of tailings facilities in the form of manuals, technical papers, conference proceedings and textbooks (Anglo 2005). There are presently three countries that the main driving force behind current international tailings management guidance. These are Canada, Australia and South Africa, all of which have very active mining industries and a large number of tailings storage facilities. Davies (2001) reports that Quebec has 65 facilities, British Columbia 130, Western Australia 350 and South Africa 400. The Department of Mines, Indusrty Regulation and Safety of Western Australia reported in 2019 that there are now more than 800 tailings facilities with approximately two thirds considered closed.

Canada

Mining regulations in Canada are controlled by the provinces except uranium mining which is regulated by the Federal Government. There are also other federal environmental laws that relate directly to the mining industry, particularly where the receiving environment is concerned (Anglo 2005).

In 1998 the Mining Association of Canada (MAC) published A Guide to the Management of Tailings Facilities. This guide was prepared by the Canadian mining community and is designed to assist mine operators in developing a successful management system for their tailings facilities. It covers each stage of tailings management from design through construction, operation and then closure and reinforces the integrated nature of each element (Brehaut 1998). Its purpose is to provide information on safe and environmentally responsible management of tailings facilities, to help mine operators develop tailings management systems that include environmental and safety criteria, and to improve the consistency of application of sound engineering and management principles to tailings facilities (MAC 1998).

MAC published a follow up manual in 2003 entitled, Developing an Operation, Maintenance and Surveillance Manual for Tailings and Water Management Facilities. This manual was developed to compliment the 1998 guide with a view to focusing on the day to day operations of a tailings facility. The need for this manual became apparent in 2000 when mining companies were demonstrating a significant progress in adopting and implementing tailings management systems (MAC 2003). The manual draws on sound industrial practice and procedures and was prepared by tailings experts within the Canadian mining community.

In 1999 the Canadian Dam Association (CDA) revised its Dam Safety Guidelines to include tailings dams (Szymanski 1999). MAC and other contributors helped to develop and incorporate tailings facilities into CDA’s guidelines (Hurndall 1998) meaning they now have the same level of respect as conventional dams. Martin et al. (2002) report that the revised guidelines focus on the responsibility for dam safety, scope and frequency of dam safety reviews, the need for an operating manual and emergency planning.

The MAC guide and manual and the CDA guidelines are intended to complement government regulations and promote due diligence of a mineral operator (Anglo 2005). The overall goal is to protect the environment and the public from the hazards associated with tailings storage.

The MAC guide and manual are later scrutinised in the PhD thesis to establish how they can be adapted to create a fundamental management structure.

Australia

Australia mining regulations, similar to Canada, are controlled by individual states. In Western Australia, the Department of Minerals and Energy (DME), through administering the Mining Act 1978, Mining Act Regulations 1981, Mines Safety and Inspection Act 1994 and Mine Safety and Inspection Regulations 1995, regulates safety and environmental aspects of tailings disposal in Western Australia (DME 2000). In Victoria, the Minerals and Petroleum Division (MPD) of the Victorian Department of Primary Industries (DPI) is responsible for regulating the minerals, petroleum and extractive industries within Victoria and its offshore waters, including Commonwealth waters. The MPD manages the administration of the Mineral Resources Development Act 1990 and the Extractive Industry Development Act 1995 (DPI 2003). In Queensland, tailings storage facilities are regulated under the Environmental Protection Act 1994 (Robinson 1999).

In Tasmania a mining lease is required under the Mineral Resources Development Act 1995. Dam safety is handled under The Water Management Act 1999 which highlights in part 8, the regulations on dam construction maintenance and decommissioning. The Assessment Committee for Dam Construction (ACDC) manage this program and have to give their recommendations in any permit issued under the Environment Management and Pollution Control Act 1994 (EMPCA). Mineral Resources Tasmania (MRT) impose rehabilitation bonds on tailings projects as they progress. Environmental management plans are required for mines under (EMPCA) and waste handling, rehabilitation and discharge are covered under this Act (Grun 2005). There are no specific regulations or tailings management guidelines for tailings storage facilities in Tasmania.

In South Australia there are no specific regulations on tailings storage and guidelines for tailings impoundment construction and operation have been adopted from Western Australia and Victoria. South Australia, like many other mining regulators, is moving away from prescriptive regulations and more on to objective and risk management. This ultimately reduces the regulators exposure to risk in case of a project failure.

Australian tailings guidance manuals are commonly referred to by tailings personnel within Australia and internationally. The DME in Western Australia have produced two guidance manuals to improve tailings management. The Guidelines on the Safe Design and Operating Standards for Tailings Storage (DME 1999), are intended to provide a common approach to the safe design, construction, operation and rehabilitation of a tailings facility, and to provide a systematic method of classifying their adequacy under normal and worst case operating conditions (DME 1999). All tailings storage facilities in Western Australia are designed and built to these guidelines (DME 2000). For the operational stage of a tailings facility the DME require a site-specific operating manual for every TMF (Anglo 2005). Each manual should be prepared in accordance with the Guidelines on the Development of an Operating Manual for Tailings Storage (DME 1998). It is a requirement to periodically review and update operating manuals as well as audit each tailings facility. The DME have another guideline document that reiterates their 1996 release. The Water Quality Protection Guidelines No.2 – Tailings Facilities (DME 2000) is designed to be used to manage the impacts that tailings storage has on the quality of the region’s water resources (DME 2000).

The two MAC manuals follow a similar trend to the two DME guidance documents. Both organisations published guidance manuals, one focusing on design, construction, operation, closure and aftercare, and the other specifically on the operational stage of a TMF’s life cycle. Perhaps both organisations realised that not enough attention to detail had been given to the day to day operational procedures of a tailings storage facility and how important they are in any tailings management system.

The Environmental Protection Agency (EAP) of Australia produced a document in 1995 entitled, Tailings Containment. The document is part of a series of best practice in the mining industry aimed at protecting the environment and encouraging ecological sustainable development. Tailings Containment focuses on the design options of a TMF to reduce the long term environmental impacts, the need for monitoring during the operational stage and the overall objectives of tailings storage (EPA 1995). Martin et al. (2002) report that this document outlines key principles that contribute to tailings management operations within Australia.

The Department of Primary Industries (DPI) in the state of Victoria has produced a comprehensive manual on tailings management. The document entitled, Management of Tailings Storage Facilities sets out regulatory policies and provides guidelines for tailings storage in the state of Victoria (DPI 2003). A clear and concise overview of tailings management throughout the life cycle of a tailings storage facility is presented. Statutory conditions are mentioned outlining what a mineral operator is required to achieve to fulfil the expectations of the regulators in the preliminary design through to closure of a TMF.

The Ministerial Council on Mineral and Petroleum Resources (MCMPR) and the Minerals Council of Australia produced a document in 2003 entitled, Strategic Framework for Tailings Management. This document focuses on stewardship, stakeholder engagement, risk management, implementation and the closure aspects of tailings storage (MCMPR and MCA 2003). The document is not intended to provide a detailed set of guidelines on tailings management but compliment tailings regulations and other tailings guidance manuals implemented across all of Australia’s jurisdictions. The goal of this document is to establish regulatory and industrial input to develop more consistent guidelines for tailings storage within Australia.

South Africa

Mining in South Africa is regulated by the Water Act 1998, the Minerals Act 1991 and the Mine Health and Safety Act 1996. The Department of Minerals and Energy (DME) is responsible for implementing the provisions of the Acts (Anglo 2005).

The principle management guidance document for tailings facilities in South Africa is the Code of Practice for Mine Residue Deposits published by the South African Bureau of Standards in 1998. The standard referred to as SABS 0286:1998 (later renamed to SANS 10286) contains fundamental objectives, the principles and minimum requirements for best practice, all aimed at ensuring that no unavoidable risks, problems and/or legacies are left to future generations (Kilani 1998). The standard was developed as a consequence of a major tailings impoundment failure in Virginia in the Free State in February 1994. The tailings escaped into the suburb of Merriespruit killing and injuring people as well as causing vast environmental destruction (SANS 1998). A detailed discussion of this failure is presented in the casestudy section of this website.

The standard does not address the environmental issues or health and safety concerns of tailings storage, but places more focus on the need for management throughout the life cycle of a TMF. The standard was initiated primarily to address safety concerns relating to structural failure of a TMF and how to prevent this from occurring. The key principles on which the SABS standard is based are (taken from (SANS 1998)):

Tailings management in South Africa is regulated by law in the Guideline for the Compilation of a Mandatory Code of Practice on Mine Residue Deposits issued by the DME in 2000. This guideline makes implementation of a code of practice mandatory for each tailings facility with compulsory adherence to the SANS 10286, Code of Practice for Mine Residue Deposits (Anglo 2005).

In July 2015, the Mining Residue Regulations (MRR) was established by the Department of Environmental Affairs (DEA) to control mine waste dumps, stockpiles and tailings storage.

Chile

In Chile the Servicio de Minas del Estado is responsible for regulating tailings impoundment projects as well as the safety of the workforce employed to manage tailings storage (Decree86 1970). Supreme Court Decree No.86 entitled, Regulation for the Construction and Operation of Tailings Impoundments was produced in 1970 and presents very basic tailings management requirements. This decree was developed as a consequence of the strong earthquake in Central Chile in 1965 that caused the failure of several tailings dams constructed using the upstream method (Anglo 2005). This guidance document is now outdated and is not suitable to help an operator develop a management strategy for their tailings storage facilities.

In 2004, the Mining Safety Regulation was created under Supreme Decree No. 132. This regulation aims to establish a general regulatory framework to which mining companies must abide and protect employees and communities. It also sets out requirements that the facilities and infrastructure of mining operations must be controlled.

In 2007, Supreme Decree No. 248 Regulations for the Approval of Design, Construction, Operation and Closing Projects for Tailings Deposits was issued. This document regulates the procedure for approving tailings storage deposits. The document highlights the design, construction, operation and closure procedures for tailings storage facilities in Chile. All mining operations that discharge/store tailings are obliged to comply with this regulation. The construction and operation of tailings deposits is also regulated by the Water Code under article No. 294

.Law 20,551 requires that all mining operations have a closure plan approved by the National Geology and Mining Service (SERNAGEOMIN), prior to the start of extraction operations.

Law 20,819 introduced changes to the mining and mine closure law, particularly with regard to the definition of operational life and the constitution of guarantees, with special reference to medium and small mining sectors. This law also modified Decree Law No. 3,525 of 1985, which created SERNAGEOMIN.

SERNAGEOMIN has prepared methodological guidelines for the presentation of closure plans and technical criteria, to guide companies in relation to the different requirements. These guides are found on the Service's website.

Other countries

In 1996 a strong earthquake caused the failure of several tailings facilities in Peru. As a consequence law enforced mining companies to conduct stability analysis of both active and decommission tailings facilities (Anglo 2005). Peru now has seventeen protocols and guidelines addressing environmental monitoring and design specifications to protect the environment. Topography in Peru is extreme, tailings dams are constructed to great heights, earthquakes are frequent and hydrology is not well understood (Martin, Davies et al. 2002).

The challengers associated with tailings storage are perhaps more complex than those in countries with suitable tailings management guidance and regulations, such as Canada. However, Peru and other countries would benefit considerably as a result of worldwide standardisation of tailings management similar to the ISO standards that are becoming increasingly more common.

In the USA mining regulations are controlled by individual states (Anglo 2005). As a consequence the regulations controlling tailings storage in the USA are varied. In 1994 the Environmental Protection Agency (EPA) published a document specifically targeted at tailings storage entitled, Technical Report – Design and Evaluation of Tailings Dams. This document is a cut down version of Steven Vick’s book entitled, Planning, Design, and Analysis of Tailings Dams (Vick, 1990) and presents the fundamentals of tailings storage, similar to those discussed in the majority of this web site. The technical report lacks management guidance but has been written to target regulatory agencies in individual states and give them a basic understanding of tailings. The document has also been written to take into account public concerns.

In Malaysia mining legislation is limited in scope because it deals almost exclusively with small scale tin mining operations. Malaysia is proposing new regulations on larger hard rock mining which includes requirements for tailings management (Stewart 1998).

In the Philippines, there is really no detailed and specific regulatory legislation relating to tailings management. Tailings management operates within a mutually reinforcing legislative framework and can be considered under, pollution prevention legislation, general environmental framework legislation and resource conservation legislation (Cabalda, Velasco et al. 1997). Presidential Decree 984 highlights the procedures for obtaining construction and operating permits of a tailings storage facility and Philippine Mining Law of 1995 (or Republic Act No. 7942) and the Department of Natural Resource (DENR) Administrative Order No. 96-40 control the environmental impacts throughout the life cycle of a tailings storage facility. Each mine has an Environmental Compliance Certificate (ECC) that essentially reinforces the prevention of impacts to the environment from a tailings facility.

These ECC’s focus on the stability and integrity of a tailings facility and the risks to third parties (Cabalda, Velasco et al. 1997). Other countries not discussed may have regulations, either directly or indirectly controlling tailings storage activities. If present, these regulations focus on the construction, operation and closure as well as the impacts on the surrounding environment. For example, in the UK tailings storage is regulated under the Environmental Protection Act 1990, The Water Act 1989 and The Mines and Quarries (Tips) Act 1971. In addition to these if a tailings facility holds more than 25,000 m3 of water above the natural level of the adjoining land it is also regulated by the Reservoirs Act 1976 (Anglo 2005). These regulations protect the environment and require a designer to be competent. The actual day to day management requirements of a tailings facility are excluded. This research is focusing on the management aspects of tailings storage and not the controlling regulations. Although these are important they fall outside of the scope of this research. As a consequence Chapter 4 of the PhD thesis identifies the weaknesses with tailings regulations and how they can be improved to establish and enhance tailings management at any mine site.

Organisations providing tailings management guidance

The manuals and guides previously discussed for Canada, Australia and South Africa constitute the main guidance for establishing a universal framework for managing a tailings facility. Alongside these guidance manuals are independent organisations such as ICOLD and its member countries, UNEP and ICME who have attempted to address tailings safety independently to regulators.

ICOLD and its member countries

For over three decades the International Commission on Large Dams (ICOLD) have addressed tailings safety and management concerns. ICOLD established a committee on tailings and waste rock lagoons in 1976 and have since published eleven bulletins specific to tailings storage (Penman 1998). Below lists ICOLD’S publications on tailings storage.

| Bulletins | Description |

|---|---|

| 44 | Bibliography: Mine and Industrial Tailings Dams and Dumps. (1982) |

| 44a | Bibliography: Mine and Industrial Tailings Dams and Dumps. (1989) |

| 45 | Manual on Tailings Dams and Dumps. (1982) |

| 74 | Tailings Dam Safety – Guidelines. (1989) |

| 97 | Tailings Dams – Design of Drainage. (1994) |

| 98 | Tailings Dams and Seismicity – Review and recommendations. (1995) |

| 101 | Tailings Dams – Transport, Placement and Decantation. (1995) |

| 103 | Tailings Dams and the Environment – Review and recommendations. (1996) |

| 104 | Monitoring of Tailings Dams – Review and recommendations. (1996) |

| 106 | A Guide to Tailings Dams and Impoundments – Design, construction, use and rehabilitation. (1996) |

| 121 | A Guide to Tailings Dams and Impoundments – Design, construction, use and rehabilitation. (1996) |

| 130 | Risk Assessment in Dam Safety Management. A reconnaissance of Benefits. Methods and Current Applications A reconnaissance of benefits, methods and current applications (2005) |

| 139 | Improving tailings dam safety - Critical aspects of management, design, operation and closure. Critical aspects of management, design, operation and closure (2011) |

| 153 | Sustainable design and post-closure performance of tailings dams (2013) |

| 154 | Dam safety management: Operational phase of the dam life cycle (2017) |

| 168 | Recommendations for Operation, Maintenance and Rehabilitation (2017) |

The United States Committee on Large Dams (USCOLD) produced a document in 1994 that focused on cataloguing historic tailings failures. Martin et al. (2002) report that this document was probably the first attempt to publish information on tailings dam incidents and their technical causation. In 2001 ICOLD’s bulletin 121 further developed the USCOLD’s tailings failure database. This ICOLD bulletin focuses on these failures by determining their cause and how they can be prevented in the future. It is targeted at those in charge of tailings dams to understand some of the simple mistakes that occur (Penman 2001). The bulletin essentially determines that there is a lack of consistent application of expertise to maintain an appropriate standard of care (Martin, Davies et al. 2002). In other words a tailings management system needs to exist, be adapted to change and be implemented efficiently and effectively.

The Australian National Committee on Large Dams (ANCOLD) issued Guidelines on Tailings Dam Design, Construction and Operation in 1999 and subsequently produced an update in 2012. The document gives guidance on the planning, design, management, construction, operation and closure of a tailings facility. The document focuses on developing a systematic approach to tailings storage and highlights that continuous management is a fundamental planning principle (Anglo 2005).

ANCOLD guidelines are applicable for water or tailings dams with the potential to cause loss of life or significant environmental or physical damage through operation or failure. Although prepared for dams which would normally be at least 10 to 15m high ANCOLD guidelines can also be used to assist with decisions on smaller dams, particularly where a dam or series or dams creates the potential for loss of life or significant damage.

ANCOLD guidelines are not a design, construction or operation code and practitioners must apply their own considerations, judgments and professional skills when designing, operating and managing dams.

Bulletins 106 and 121 were joint publications by ICOLD and the United Nations Environmental Programme (UNEP).

UNEP and ICME

The United Nations Environmental Programme (UNEP) and the International Council on Metals and the Environment (ICME) have organised two seminars (1997 and 1998) on tailings management. The 1997 workshop focused on the fundamentals of tailings management and addressed issues relating to design, construction, monitoring, community consultation, contingency planning and auditing. Operating and closure strategies were also discussed. The success of this workshop prompted UNEP and ICME to organise the 1998 event which addressed specific topics of risk assessment and contingency planning in the management of tailings. Both workshops were attended by experts in tailings from all over the world (ICME, SIDA et al. 1997; ICME and UNEP 1999).

In October 1998, UNEP and ICME released a joint publication, Case Studies on Tailings Management to provide examples of sound tailings management (ICME and UNEP 1998). In 2000, ICME commissioned Golder Associates to review the adequacy of tailings management guidelines (ICOLD and UNEP 2001). In October 2000 Golder published, A Case for an International Guide for Tailings Management which gives an overview of existing regulations and guidance procedures for tailings management from mining jurisdictions around the world (Anglo 2005).

UNEP became involved with tailings management through the well publicised tailings impoundment failures in Guyana (Omai) and the Philippines (Placer and Marcopper). In 1996 UNEP surveyed tailings related incidents and published ICOLD’s bulletin 106, A Guide to Tailings Dams and Impoundments – Design, construction, use and rehabilitation. There is ongoing liaison between ICOLD and UNEP to see what lessons can be learned from past failures, to look at regulatory instruments in use, and their effectiveness (Balkau 1998).

In 2000, the Government of Australia and UNEP co-hosted the first intergovernmental seminar entitled, Workshop on Environmental Regulation for Accident Prevention in Mining: Tailings and Chemicals Management. UNEP is working with interested governments to establish an ongoing Regulators Forum – with the safety and environmental performance of tailings facilities and approaches to their regulation as a continuing theme (ICOLD and UNEP 2001).

ICMM

The International Council on Mining and Metals (ICMM) represents 23 of the world's largest mining and metals companies and recognizes the significant role that mine tailings plays in the overall risk profile of mining operations worldwide. Following from the Samarco tailings dam collapse in Brazil in 2015 and the earlier Mount Polley failure in Canada in 2014, ICMM's members unanimously agreed to respond as an organization with a commitment to leadership in environmental and safety performance within the mining and metals industry.

The response has been to convene a global review of tailings storage facility standards, guidelines and risk controls. The review has been led by ICMM and has included external experts and member company representatives. The review focuses on corporate level surface tailings management across the membership, including standards, guidelines and risk controls, governance and emergency reparedness related to the prevention of and response to sudden catastrophic failure of tailings storage facilities.

International Institute for Environment and Development (IIED)

The Mining, Minerals and Sustainable Development (MMSD) is a project of the International Institute for Environment and Development (IIED). In April 2002 they published a document on tailings, its environmental impacts and methods of storage. The document entitled Mining for the Future Appendix A: Large Volume Waste Working Paper is mainly focused around the impacts on the environment as a consequence of river and sea disposal of tailings (MMSD 2002). The document does address tailings management but is unique with respect to other tailings documents in that it provides a precise and frank overview of tailings disposal to natural water bodies.

International Organisation for Standardisation (ISO)

The International Organisation for Standardisation (ISO) has produced many standards that help any organisation with their quality and environmental control. These standards are voluntary for any organisation to implement and not only show independent dedication to safe and sound operation, they also gain a worldwide recognised compliance. Two of ISO’s main standards are ISO 9000 and ISO 14000. ISO 9000 focuses on improving quality management within any organisation to enhance customer satisfaction and promote continual improvements to operational performance. ISO 14000 is perhaps more specific to the research presented in the thesis accompanying this website, as this standard is primarily concerned with environmental management. In particular ISO 14001 shares common management system principles with ISO 9000 and is a basis for implementing an environmental management system (ISO 1996). For tailings management, ISO 14001 has been used to develop MAC’s A Guide to the Management of Tailings Facilities which reiterated and developed the ISO 14001 environmental management system model. The ISO 14001 standard provides the necessary framework to rigorously establish responsibilities, objectives, plans and other activities for all phases of a TMF from design through to closure (Brehaut 1998). Balkau (1998) suggests that the application of these ISO standards to tailings management could in fact provide the necessary change in management perception that needs to accompany the technical standards that are already widely known.

If a mine became ISO 14001 certified (and some are), there is reassurance that tailings management strategies exist and that they are developed and assessed with overall environmental performance. Certification can assure the mining company of its compliance with environmental policies and regulator requirements and demonstrate this to others (ISO 1994).